Email:export@zetian-tech.com

Tel:+86-571-28322780

| NO. |

Measurement point |

Temperature |

Pressure |

Measurement components |

Detection purpose |

Recommend products* |

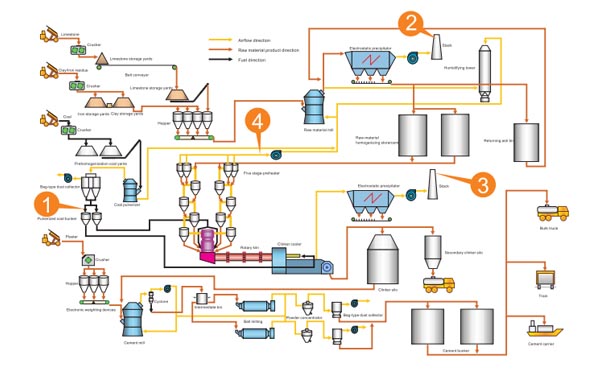

| 1 |

Grinding coal section: pulverized coal bin |

Normal |

Slight-negative pressure |

O2: 0-21% CO:0-3000ppm |

Prevent accidents or explosion in pulverized coal preparation |

LGT-100 In Situ Gas Analyzer LGT-106 Laser Gas Analyzer |

| 2 |

Preheater outlet blowdown stack |

Normal |

Slight-positive pressure |

CEM(7parameters) NH3: 0-10ppm |

Online-monitor gas components in emission gas and Real- time monitoring denitration efficiency |

EM-5 Gas Analyzer for Sale, LGT-100 In Situ Gas Analyzer, GA5000 |

| 3 |

Cooler flue gas emission stack |

Normal |

Slight-positive pressure |

CEM(4parameters) |

Online monitor dust density,temperature, pressure, flow |

EM-5 Gas Analyzer for Sale |

| 4 |

5-stage preheater exhaust gas downstream |

200℃ |

Slight-negative pressure |

CO, NOX, O2 |

Monitor fuel combustion condition adjust production device, realize production optimization |

EM-5 Gas Analyzer for Sale, LGT-180 Extractive Gas Analyzer |