Email:export@zetian-tech.com

Tel:+86-571-28322780

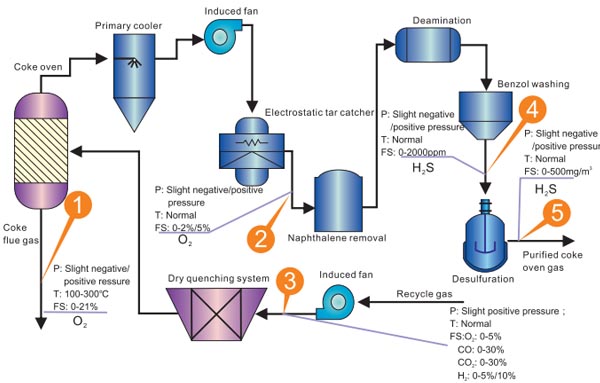

| NO. |

Measurement point |

Temperature |

Pressure |

Measurement components |

Detection purpose |

Recommend products* |

| 1 | Coke flue gas |

60-200℃ |

Slight-positive pressure |

O2: 0-21% |

Monitor fuel combustion condition |

LGT-100 In Situ Gas Analyzer |

| 2 |

Electrostatic tar catcher downstream |

Normal |

Slight-positive pressure |

O2: 0-5% |

Recovery and utilization of coke oven gas |

LGT-100 In Situ Gas Analyzer |

| 3 |

Blower downstream |

180-260℃ |

Slight-positive pressure |

CO: 0-30% CO2: 0-30% O2: 0-5% H2: 0-10% |

Process safety control |

LGT-180 Extractive Gas Analyzer |

| 4 |

Before desulfuration |

/ |

/ |

H2S: 0-1000ppm |

Monitor desulfurization efficiency,prevent corrosion of the process dpipelines and devices |

LGT-200 Laser Gas Analyzer |

| 5 |

After desulfuration |

Normal |

Slight-positive pressure |

H2S: 0-200ppm |

Monitor desulfurization efficiency,prevent corrosion of the process pipelines and devices |

LGT-200 Laser Gas Analyzer |