Email:export@zetian-tech.com

Tel:+86-571-28322780

| NO. |

Measurement point |

Temperature |

Pressure |

Measurement components |

Detection purpose |

Recommend products* |

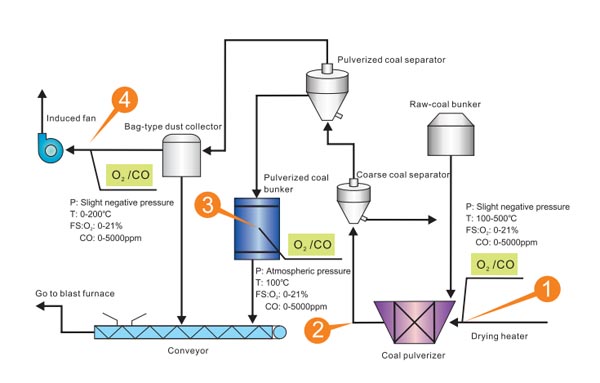

| 1 |

Coal pulverizer entrance or hot-blast stove emission gas down stream |

100-350℃ |

Slight positive pressure |

O2: 0-21% CO: 0-3000ppm |

Security monitoring, prevent exposion | LGT-100 In Situ Gas Analyzer |

| 2 |

Coal pulverized down stream |

100-350℃ |

/ |

O2: 0-21% CO: 0-3000ppm |

Security monitoring, prevent exposion | LGT-106 Laser Gas Analyzer |

| 3 |

Pulverized coal bunker |

Normal |

Slight positive pressure |

O2: 0-21% CO: 0-3000ppm |

Security monitoring, prevent exposion | LGT-106 Laser Gas Analyzer |

| 4 |

Bag-type dust collector |

200℃ | / |

O2: 0-21% CO: 0-3000ppm |

Security monitoring, prevent exposion | LGT-100 In Situ Gas Analyzer |